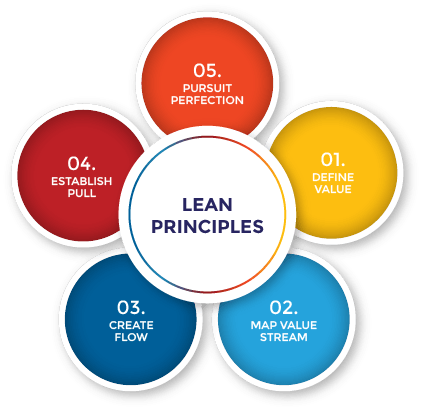

Lean Methodology

An optimized version of the Agile Methodology that emphasizes reducing waste and improving efficiency in the interest of providing more value to users.

Click here to learn about each step!

Define Value

- Understand customer needs and values. What is the customer looking for in a (fill in the blank)?

- Streamline the process based on customer needs, which eliminates unnecessary spending on things the customer won’t value

Map Value Stream

- Identify and map all the steps and resources involved in delivering the product or service

- Like the “plan” step of Agile Methodology

Create Flow

Address any potential roadblocks before starting the plan, to avoid expending resources unnecessarily

Establish Pull

Production should be based on actual customer demand, thereby minimizing waste associated with overproduction and excess inventory

Pursue Perfection

Continue seeking ways to reduce waste and improve processes

Slideshow!

View the information on this page in a slideshow format! Useful for classrooms and all other group settings.

Learning Objectives

- Understand the Lean Philosophy: Describe the principles of Lean, including continuous improvement, waste reduction, and maximizing customer value, and explain their relevance to project planning.

- Identify Value and Waste: Recognize and classify value-adding versus non-value-adding activities, and identify the five types of waste in a project workflow.

- Measure and Evaluate Lean Success with Metrics: Identify and utilize key Lean metrics, such as cycle time, lead time, and throughput, to measure project performance and guide decision-making for continuous improvement.

Characteristics

- Eliminates waste of multiple forms

- Motion – movements of people, materials, or machines are more complicated or occur more frequently than necessary

- Inventory – too much stock → loss of valuable storage, management, and overall loss of value over time

- Time – processes or interrupted and/or idle, costly

- Overproduction

- Human Potential – not getting the most out of people

- Encourages teams to document effective processes

- Customer-centric

- Cost-effective, decreased resource → lower prices → happy customers

Benefits

- Increased Efficiency and Productivity

- Enhanced Quality

- Reduced Costs

- Faster Delivery Times

- Better Customer Satisfaction

- Higher Employee Engagement and Morale

Drawbacks

- Cutting back too much

- Relies on every team buying into principle

Example

- Amazon uses lean management principles in its fulfillment centers

- Pick-to-Belt Process: Products are stored on shelves ready for shipment. Workers pick them and place them on conveyor belts, which lead to the parking area.

- 5S System: All workspaces are organized in a way that ensures maximum efficiency and safety.

- Kaizen: A continuous improvement process that originates from Japan, in which employees are encouraged to identify and eliminate waste from their work processes.

- Just-in-Time Inventory: An inventory management system that minimizes the amount of inventory on hand, significantly reducing the costs and risk of obsolescence

How Can We utilize this approach?

- Lean methodology is useful for projects that have limited resources, including time, money, and other facilities. This methodology ensures one can produce quality products with limited resources

- Promotes SDG #11: Sustainable Cities and Communities. Development practitioners working with resources that are not in abundance, or that are harmful after a certain extent, can use lean methodology to conserve them. Development practitioners with limited resources can also benefit, as the lean methodology maximizes impact even with limited resources.